Researchers at the SUNY College of Environmental Science and Forestry are developing ways to use cellulose from wood to strengthen plastics, providing a lightweight component that has the added advantage of being biodegradable.

The key is pulling nanocrystals of cellulose out of natural materials, ranging from trees and willow shrubs to orange pulp and the pomace left behind after apple cider production, and mixing them with plastics.

“By adding an ounce of crystals to a pound of plastic, you can increase the strength of the plastic by a factor of 3,000,” said Dr. William T. Winter, a chemistry professor and director of the Cellulose Research Institute at ESF. “And in the end, in a landfill, it’s just carbon dioxide and water, which can be taken up and made into more biomass.”

The process provides another use for the one billion tons of biomass than can be produced annually in the United State, according to an estimate from the U.S. departments of energy and agriculture. The term “biomass” refers to any biologically derived material.

“All plant materials contain a minimum of 25 percent cellulose,” Winter said. “Wood from trees is a little higher, between 40 percent and 50 percent.”

In addition to being used as strengtheners in plastics, the nanocrystals can be used in ceramics and in biomedical applications such as artificial joints and disposable medical equipment. Using cellulosic nanocrystals to strengthen plastics has advantages over the glass that is often used: Glass is heavier, harder on processing machinery and therefore more expensive to work with, and it stays in the ground for centuries. The cellulose nanocrystals will break down quickly in a landfill.

“Anything which is made in nature can be destroyed in nature,” Winter said. “And these cellulose particles have a lifetime in a landfill of less than 90 days, at which time, they go back into carbon dioxide and water. It can be reabsorbed by other plants that use it to make more cellulose.”

“Just one word: Plastic!”

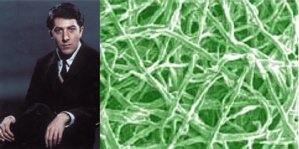

And Dustin Hoffman has what to do with this story? I would have thought oprah would have been pick or maybe Randy Johnson.

Tee-Hee. Never saw the graduate, eh?

Anything to prevent self-replicating nano robots from working our landfills and then taking over the world when they run out of materials within reach.

/programmed with silly code that says Break down all complex molecules to simpler ones, explore when no more in range…

I have seen the graduate, i just dont remember the part where they discover better ways to make plastic.

sorry ya im wrong.

Cellulose nanocrystals BY THEMSELVES will biodegrade in 90 days in a landfill. But not if it constitutes 6% of a mix with petrochemical plastic. Bacteria won’t fit in the nanometer “wormholes”.

The nanocrystals would make the plastic last a lot longer. As the resins evaporate out of the plastic it becomes more brittle to tensile stress. But the nanocrystals will act like rebar, holding it together.

Ultimately, they will reduce the petrochemical plastic to the thickness of paper with a honeycomb structure — and then use a thicker bond breaker in the molds to preserve the nanocrystals.

On what fantasy planet does this statement apply concerning plastic:

“And in the end, in a landfill, it’s just carbon dioxide and water, which can be taken up and made into more biomass.”

Plastic is not biodegradable. The stuff that you mix in it is trapped by a coating of plastic, making it non-biodegradable.

Is this announcement brought to you by the same people that advertise for the nuclear industry (safe clean power) or the coal industry (zero greenhouse emissions)? Same kind of bullshit.

When can I get my first completely plastic car? Don’t you wish everything was Rubbermaid™?

Nice piece of fantasy Timbo. Are you at the same screenwriters’ conference as Uncle Dave? You’re only one step ahead of Awake, I see.

You dudes are sitting here, probably not even reading the link much less carrying on further to the research papers — which are also available online btw.

Statements of attainder have even less to do with science than they do with politics.

Funny,

sounds like the same process as Fiberglass…DUH

Sounds the same to me, too, bro.

Now, can we send broadband through it? 🙂

Or use REAL fiber optic, lines and Lite up the car…

Talk about GLOW in the dark.

A few years ago there ware experiments to add carbohydrates to the plastic which would also make it biodegradable. I wonder what ever happened to that idea.

#13….Mr. Fusion….the Atkins diet????

Wow, adding wood fiber to plastic – let’s call it Bakelite!

Dustin Hoffman was told to invest in plastics – that’s the significance of his picture. I’m guessing. Many synthetics are produced from coal tar resin, a product of processing oil or coal I believe. Oil pumped from the ground and coal, are compressed plant and animal matter and even the new production of nylon from plant and farm animal waste with less carbon bonds is still a combination of plant materials. I guess the real advantage to the lightweight strong material would be if it was not eaten by termites or attacked by mold or fungus and could be used in the construction of structures. Let the trees grow thick on our planet, produce the oxygen we all breathe, and maybe with the added strength and durability, less plastic would be finding its way into the landfills etc.

Mr Fusion, A few years ago there ware experiments to add carbohydrates to the plastic which would also make it biodegradable. I wonder what ever happened to that idea. Starch = carbohydrate

They’re doing it, you can buy products made of it now: http://www.mindfully.org/Plastic/Biodegradable-Plastic.htm

—-

Unfortunately we don’t really know what 3000 times stronger means based on the article. Is that tensile strength ? (we could have incredibly strong nylon rope that would still give and melt) or compressive strength (maybe have lots more plastic in car bodies, or even platic car frames). It doesn’t say anything about making platic more rigid or more temperature resistant (imagine walking outside in the middle of a midday Las Vegas sun and seeing that your car body had melted)

—-

The question of what to do with composites like cellulose-platic or paper-cement or carbon fiber reinforced materials when they’ve ended thier usefull lifespans is an interesting one. But I think the windhexe could potentially solve at least some of those issues.