Because of the decreasing availability of oil, interest has been renewed world-wide in the production of liquid hydrocarbons from carbon monoxide and hydrogen using metal catalysts, also known as Fischer-Tropsch Synthesis.

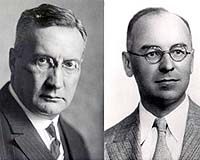

Ninety years ago as well as today, the Max Planck Institute of Coal Research has been at the centre of scientific experimentation in the field of catalytic chemical reactions. On the 15th of December, a colloquium will look back at the trailblazing new procedure invented by Franz Fischer and Hans Tropsch eight decades ago.

The required gas mixture of carbon monoxide and hydrogen -the so called synthesis gas – is created through a reaction of coke or coal with water steam and oxygen, at temperatures over 900 degrees Celsius. In the past, town gas and gas for lamps were a carbon monoxide-hydrogen mixture, made by gasifying coke in gas works. In the 1970s it was replaced with imported natural gas (methane). Coal gasification and Fischer-Tropsch hydrocarbon synthesis together bring about a two-stage sequence of reactions which allows the production of liquid fuels like diesel and petrol out of the solid combustible coal.

Given the quick rise in the price of crude oil – and the dramatic consequences of this year’s hurricane season for American oil production and processing – the US is rethinking how it deals with its large domestic coal inventory. In 2006 the first US coal-to-diesel production facility is planned in Gilberton, Pennsylvania.

I grew up in a city where coal gas was in common use before the introduction of natural gas. Even though natural gas was cheaper [at the time], the big fear was over people dying because it was odorless compared to coal gas. And until an artificial odor was added — that’s exactly what happened when pilot lights blew out and no one noticed the gas was still on.

Here’s what we do…

We pool our funds and buy land on Iceland near enough to one of the geothermally active volcanoes and open a coal gasification plant.

We buy coal from the US and have it shipped to Iceland; convert it from solid coal to coal gas and from there to this synthetic liquid fuel.

The reasons we need to do it in Iceland are:

1) easy access to inexpensive geothermal energy for the coal gasification plant

2) short shipping distance from the US and Europe to Iceland for both raw materiels and finished product

3) real estate is less expensive than Hawaii

4) By buying raw materiels in the US and producing it in Europe, we get tax breaks from both economic powers.

I’ve got a few $$s…who’s with me?

G

“decreasing availability of oil”? a little premature.

That depends on whether you think the “decreasing availability” is due to reduced supply, or increased demand – doesn’t it?

As the article mentions, near the end:

“Given the quick rise in the price of crude oil – and the dramatic consequences of this year’s hurricane season for American oil production and processing – the US is rethinking how it deals with its large domestic coal inventory.”

And we may not need G’s volcanoes if we can use the newer solar reflector/concentrators to achieve 900C.

link: http://www.stirlingenergy.com/

Okay, lets pool our resources and buy some old abandoned oil wells in West Texas with a nearby railhead…we forget about Europe and we pay BNSF to bring the rail to our “refinery.”

G

Thish has been done for decades on a commercial scale in South Africa. Check out http://www.sasol.com.